Laser based approach to measure the key parameter indices (KPI) such as vibration in case of bridge, or motor; electric current for monitoring motor health are few examples of critical infrastructure. Though contact based sensor such as accelerometers are widely used, they suffer from loading effect, difficult to place them and operate them. These draw backs are addressed by laser based non-contact and non-destructive sensor to measure the KPIs of critical infrastructure. Laser based sensors typically consist of:

– Laser: source of electromagnetic energy

– Optical components: lens, beam splitter that helps to guide the laser emission to object under test

– Photodiode: receives the reflected electromagnetic radiation that contain information about the remote target under test/observation

In this work, under the supervision of Associate Professor Ajit Jha (Department of Engineering Sciences (Mechatronics), I have worked and developed different components that could be integrated together to be used in laser based systems for critical structures monitoring e.g. bridge / and or electrical motors. Following tasks was undertaken and completed.

Task 1: Design of laser modulator:

In this task, we retrofitted the EK2000 laser driver (from Thorlabs) to be used for L68P040 laser diode. The circuit was designed such that the laser could be operated under bias and under external modulations both, thus adding flexibility to the mode of operations.

Task 2: Design of transimpedence amplifier:

Generally laser (L68P040) sensors work by incidenting laser beam on the target under observation, the target reflect the incident beam that is received by photodiode. The reflected beam collected by photodiode (FS025) is then further processed to retrieve the related parameters. However, the reflected beam is very weak and the amplification is required to increase the signal to noise ratio (SNR).

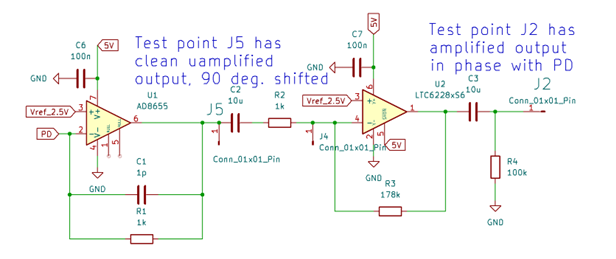

So, a two-stage amplifier circuit was designed, developed and built to amplify the signal from photodiode. The amplifier consists of a transimpedance amplifier and a voltage amplifier in negative feedback. The circuit achieved a bandwidth range from approx. 300 Hz to 650 kHz without significant attenuation after the second amplifier stage.

Task 3: Data acquisition pipeline and automation :

After, the laser driver (task 1), amplifier (task 2) was completed, finally an automated data acquisition pipeline was developed in LabVIEW to acquired signals from photodiode with ease without interrupting the experiment. A simple LabView VI program with the NI USB-6008 DAQ controller was eventually developed to retrieve and visualize voltage signals from the circuit, in order to analyze the voltage gain in real time.