Developing technology for underwater imaging is challenging. Saltwater, pressure and corrosion, place demands on every component and engineering choice that goes below, or near, the oceans.

This past semester, we worked on continuing development of an underwater multi camera system designed to capture synchronized images for 4D reconstruction. The work centered around three major tasks: designing waterproof enclosures for the electronics, developing underwater coax cables, and design and production of robust and waterproof mounting hubs for the geodesic dome structure.

This blog is regarding the students in innovation projects:

1) Utvikling av fire vann og trykktette bokser for innebygde datamaskiner.

2) Utvikling av 24 kabler og hurtigkoblinger for undervannsbruk.

3) Design og produksjon av vantette hubber og festeanordninger.

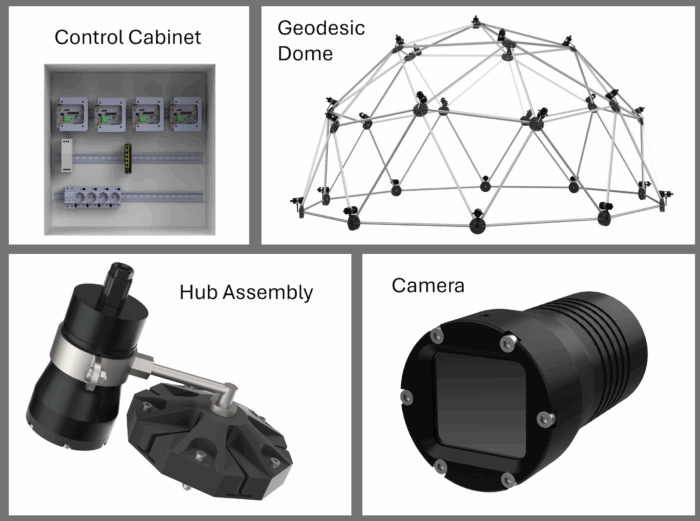

The system has four edge AI devices sharing the workload of running the system. The four NVIDIA Jetson AGX Orin computers are connected to 24 global shutter cameras from E-con systems. Al-though the cameras are placed underwater, the processing hardware remains on land and must be protected from spray, moisture, and rough handling. To achieve this, we developed a sealed control cabinet with DIN rail mounting for the important parts. This ensures that the Jetsons, the network switch, and the triggering electronics are both accessible and safe inside a rigid unit that can handle the mechanically and electrically hazardous environment near the ocean.

Each camera also needed its own waterproof and pressure resistant housings. These housings were milled from marine grade aluminum and fitted with high quality optical K9 glass and axial O-ring seals. The aluminum housings for the camera were anodized for corrosion resistance, and the final assemblies were pressure tested well beyond the system’s intended operating depth. The result is a complete set of 24 camera housings that are lightweight, durable, versatile, and reliable for underwater use.

Connecting the cameras to the Jetsons requires long, high-speed coax cables capable of carrying both data and power by the GMSL2 transfer protocol. Standard coax cables are not suitable to be submerged, so we ordered custom cables with polyurethane jackets for improved resistance and waterproofing. The electrical characteristics had to match strict requirements to avoid signal reflections or losses, especially since the system uses long cables and need a high bandwidth to maintain the best possible imaging quality.

For the waterproof connection between the cable and the camera housing, multiple connector solutions were considered. This included potted and wet link penetrators commonly used in marine robotics and ROV‘s. The final design provides a secure seal, strain relief, and the ability to separate water ingress through the cable harness into the camera housing.

The cameras are arranged around a geodesic dome designed to observe a large volume from all angles. To make the structure strong, lightweight, and easy to assemble, we redesigned all connection hubs and refined the layout. The original hubs were 3D-printed prototypes that suffered from tolerances and material shrinkage. In the updated design, they were split into two machinable components, reinforced, and produced from POM like material with a good balance between strength,

durability, and weight.

Together, these developments managed to get the research platform one step closer to the ocean depth. The waterproof housings protect each camera, the custom coax cables ensure stable high speed communication, and the strengthened dome structure maintains the geometry needed for synchronized multi view capture.

We would like to thank Associate Professor Daniel Hagen, Tonje Knutsen Sørdalen from the Institute of Marine Research and UiA for the opportunity to further improve the on the project. We would also like to thank all the employees at the UiA machine laboratory for their contribution to finding solutions and assist in production of components.