Introduction

During my second semester in the MSc Mechatronics program, I undertook two key research and innovation projects, which were combined into one comprehensive effort.

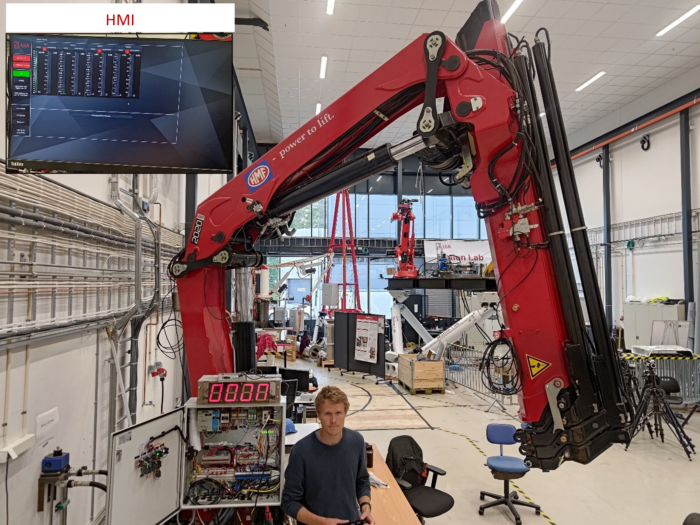

The UiA Motion Lab houses various advanced lifting and load-handling equipment used for cutting-edge research and the development of innovative motion compensation and control techniques. Among the equipment is a mobile crane, manufactured by the Danish company HMF, which was originally designed for mobile platforms such as trucks and barges. This crane has since been upgraded with a modern industrial PC (IPC) to support real-time operation and the implementation of a digital twin that runs alongside the physical crane.

Objectives

In prior projects, the crane had been fitted with a range of sensors, including position encoders and pressure sensors. However, these sensors were connected to an outdated control system from National Instruments (NI), which limited the potential for advanced model-based design in MATLAB-Simulink and hindered the development of a digital twin.

To address this, I upgraded the system by installing a Beckhoff IPC running TwinCAT automation software and a Remote Input/Output (RIO) system to interface with the sensors and actuators. The new setup provided the computational power necessary for running a real-time digital twin and developing closed-loop control systems.

The key tasks I completed were as follows:

1. Replaced the NI controller with a Beckhoff PC-based controller and connected sensors and actuators.

2. Developed software to interface with the sensors and actuators.

3. Created a modular software structure that can be expanded by other students and researchers.

4. Designed an HMI that displays essential data such as position, valve actuation, and various pressures.

5. Implemented mode selection in the HMI (e.g., Off, manual Joystick control, auto).

6. Developed a simple closed-loop controller for precise actuator control.

Learning Outcomes

Through the completion of this project, I gained significant expertise in several key areas:

1. Control System Integration: I learned how to retrofit and upgrade control systems by replacing legacy controllers with advanced IPC systems. This included the integration of sensors and actuators to enhance system performance.

2. Software Development: I developed critical skills in structuring software that interfaces with real-world hardware, enabling the control and monitoring of physical systems. Additionally, I ensured the software was modular and expandable for future use by other researchers.

3. HMI Design and Implementation: I designed an intuitive Human-Machine Interface (HMI) that allows users to visualize important system parameters, such as position, pressure, and valve actuation, while also enabling easy selection of different operation modes. This improved the user experience and control of the system.

4. Closed-Loop Control: I applied fundamental closed-loop control principles, developing control algorithms that accurately manage actuator positions, ensuring precise operation of the crane’s load-handling functions.

These experiences have given me a strong foundation in industrial automation, control systems, and mechatronics, all of which will be invaluable in my future career.

Conclusion

Throughout this project, I invested a total of 101 hours and 10,000 NOK for equipment. The mobile crane is now fully equipped with a modern, PC-based control system from Beckhoff, tailored for model-based design, and ready for further development in future student projects. This advanced control system provides an excellent foundation for research and experimentation, and it is already being utilized by myself and three other students in a collaborative project as part of the MAS513 – Advanced Robotics and MAS516 – Design of Industrial Mechatronic Systems courses. The successful implementation of this system demonstrates its potential for future research and educational use in the UiA Motion Lab.

Finally, I would like to express my sincere gratitude to my supervisors, Associate Professor Daniel Hagen (Head of UiA Motion Lab) and Professor Michael Rygaard Hansen, for providing me with this exciting project, their valuable input, and continuous support throughout the process. Their guidance was instrumental in the successful completion of this project.