Laser Optical Coherence Tomography (OCT) is a technique that uses focused light to measure and image surfaces or internal structures with very high resolution. A central element in many setups is the galvoscanner: a small mirror driven by galvanometer motors that steers the laser beam rapidly in one or two axes. By controlling this mirror, the system can scan the laser over a defined area and build up a 2D or 3D representation of the target.

This project, supervised by Associate Professor Ajit Jha at the UIA Department of Engineering and Sciences, started with the idea of building a galvoscanner from scratch. After reviewing how commercial units are designed and the precision they require, it became clear that this was outside the realistic scope for one semester. Instead, the team decided to use an SG8220-G galvoscanner and shift the focus to what we could fully deliver: a mechanical rig that holds and aligns the laser, optics, and scanner in a controlled and repeatable way.

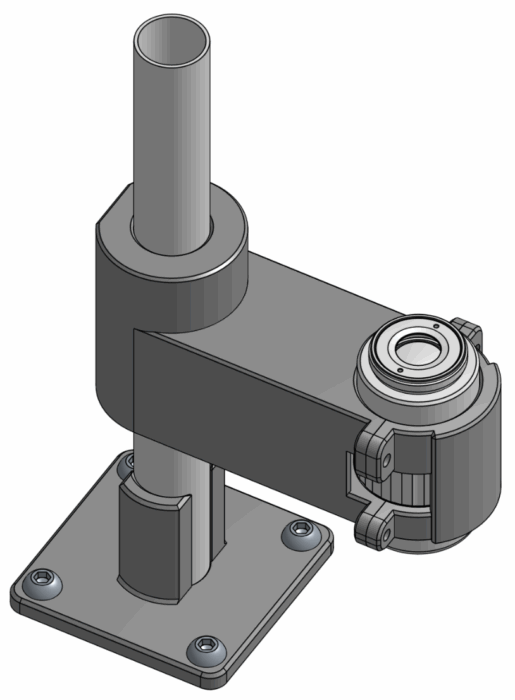

The core of the rig is a vertical steel tube that acts as the main structural element. Around this tube I designed modular holders for the key components: a MY5X-822 optic lens to focus the beam on the monitored surface, and a laser module fitted with an LT240P-B lens feeding the beam into the SG8220-G galvoscanner. Both the laser and the focusing optics need to be adjustable with millimetre-level precision, so the holders are designed to move along the tube and be rotated before being locked in place. This allows fine tuning of both focus height and beam direction.

All mechanical parts were modelled in Onshape, a web-based program that makes it straightforward to check clearances, mounting interfaces, and assembly sequence before printing. The components were then produced in PLA on an FDM 3D printer. To achieve reliable fastening, I used heat-set threaded inserts in the PLA parts, where screws would press directly onto the steel tube, providing a firm clamping force without damaging the plastic and allowing repeated adjustments.

In practice, the rig is stable, easy to adjust, and low-cost to modify. It provides a clean mechanical platform for experiments with the laser and galvoscanner, and it can be extended with additional modules if the optical setup grows more complex. In the future though, to make it more precise in movements and make it have a premium feel, it could be produced of other plastics like polycarbonate or POM. While the OCT system itself is still under development, this rig is a concrete step towards a more complete and configurable laser scanning setup.